For almost a century, little has changed in the way homes have been built, but now, building science is leading homebuilding into a new era.

A hundred-year-old or more Craftsman or Victorian home might seem a normal sight in today’s neighborhoods. However, how normal would a Model T or horse and buggy look? Technology has driven transportation incredibly far forward, so much so that people can identify the age of a photo by cars, and a new Tesla easily announces today’s date. Homebuilding has eluded dramatic technical advancements—at least until recently.

Innovation in Design

There was a time when Teton County, Wyoming was off the beaten path and less accessible by air travel, and driving the roads was slower and in bad weather, challenging. Back then, buildings and homes were generally regional, rustic, and built from logs, timbers, and stone—tough local materials, time-tested to stand up to the challenges of the climate. Now, as a resort destination, newcomers are bringing different aesthetics and new approaches to the homes they are building.

“People love the wild beauty, jagged high peaks, wilderness, and the constant reminder that nature is boss. We have to build for it,” comments Chris Moulder, AIA, partner in Dubbe Moulder Architects, an architectural mainstay in Jackson since the 1990s. “Homes must be strong to withstand the snow loads, the winds, and possible seismic events.”

Moulder continues, “People grew up with the romance of the West and initially in our practice they wanted a Western cowboy and log cabin spirit. While the appeal remains for some, it has evolved, and now there is a demand for edgy, flat-roofed steel structures. Considering there can be temperature shifts of 50 degrees in just a day, there are challenges to making these homes comfortable environments.”

Mark Dalby, partner at Teton Heritage Builders in Jackson, echoes Moulder’s opinion about the changes in building since the 1990s. “Definitely, the biggest change has been the shift in style in Jackson Hole away from rustic mountain log homes to a more modern, clean lined design, using a more minimalistic approach. Most of our clients, are building second or legacy homes and bringing their urban aesthetics and design style.”

Scott Schwab of Teton Heritage Builders adds, “The classic log homes have evolved in the past 20 years to flat roofs, glass, and structural steel.” He adds, “Whether residential or commercial, we are always building with structural steel, and many times it is left exposed. Our new challenges are to build for energy efficiency and to insulate well.”

Kurt Dubbe, AIA, partner with Chris Moulder at Dubbe Moulder Architects and veteran Jackson area architect, joins the discussion, saying, “The components of steel, glass, and stone in a stripped-down design are the basis for the mountain contemporary look. The scope and character of the individual projects vary, but the designs manipulate the same material palette to express this individuality. Having said that, I would like to add that what works best for our environment is to not be slavish to a certain style.”

“It is a very unique place, and it’s important to use intelligence and insight to determine what will work here,” Moulder notes.

“We remind ourselves that our clients benefit from enhancing two-dimensional plans into 3D models, which in turn opens the lines of communication sooner.”

–Mark Dalby, Partner, Teton Heritage Builders

Technology Enhances Communications

“More than ever, each home is a system,” Mark Dalby observes. “Designing and building them demands that collaboration happens sooner, and that closer collaboration and communication is maintained throughout the building process. Here, we rely on advances in technology. Constructing a home has always been about communications and relationships, and with the complexity of building practices and design, it is even more so now.”

“Definitely we get everybody involved ahead of time, and channels of communications open up sooner to provide timely feedback,” Scott Schwab adds.

With complex designs, software systems like 3D modeling can assist the owner to better visualize the home at an early point in the design and virtually walk through the home and make changes early in the design process. Dalby notes, “We remind ourselves that our clients benefit from enhancing two-dimensional plans into 3D models, which in turn opens the lines of communications sooner.”

Kurt Dubbe pitches in, “File sharing also allows us not only to communicate with the team and client better, but also to work with staff remotely. We have the ability to retain staff and not lose their talent if they choose to live elsewhere.”

“Technology has improved how we work in many ways,” Moulder adds. “Especially with teaming and partnering. Each of our projects is unique and has its own demands, and we want to maximize opportunities to engage as a team of talented partners.”

Chris Moulder sets forth a counterpoint to always opting to maximize technology. “Despite the power of technology, we remain old-school about first drawing our designs by hand. Abstract thought is very human. By using our hands, responding to something on paper, and applying the math, we think through the process, relying on instincts, education, and our understanding of beauty, function, and appeal. The essence of beauty is easily lost by initially designing on the computer. After we have developed the concept, then we transfer our work to the computer, and we use advanced programs with powerful technology, including AutoCAD and ArchiCAD.”

“Despite the power of technology, we remain old-school about first drawing our designs by hand. Abstract thought is very human. By using our hands, responding to something on paper, and applying the math, we think through the process, relying on instincts, education, and our understanding of beauty, function, and appeal. The essence of beauty is easily lost by initially designing on the computer.”

–Chris Moulder, AIA, Partner, Dubbe Moulder Architects

More Performance

“we have to strive for higher-quality building envelopes and mechanical systems. The latest energy regulations encourage us to take it to the next level with insulation, high-performing window systems, mechanical systems, and roof design.”

–Mark Dalby, Partner, Teton Heritage Builders

Compared to other mountain resort communities, the Jackson area has longer, colder winters. As a consequence of climate and other pressures, the local government has stricter building codes and requirements for energy efficiency than most other jurisdictions.

Mark Dalby agrees that building in Jackson requires being more mindful of energy usage and calls out that the area is in cold hardiness zone 3 (-30 to -40 degrees F). “This means that we have to strive for higher-quality building envelopes and mechanical systems. The latest energy regulations encourage us to take it to the next level with insulation, high-performing window systems, mechanical systems, and roof design.”

Because of its bold efforts, Teton County and Jackson are leaders among communities pursuing sustainable energy use policies. This may be in part because James Wolfensohn, former World Bank Chairman, challenged the community to achieve leadership in environmental innovation and sustainability. In 2006, facing a forecast of a six percent increase in energy use by 2010, Jackson and Teton County initiated 10×10: reducing total energy use by 10 percent by 2010. Part of the aggressive approach to reach such an ambitious goal was to adopt by reference a series of international codes, including the International Energy Conservation Code, the International Building Code, and the International Residential Code, and to regularly update the references as these codes modify.

Another effort is the Energy Mitigation Program, wherein people pay higher permit fees for systems that under-perform and receive financial rebates, or fee-bates, for surpassing standards. In other words, buildings are charged for energy-intensive building elements that do not meet recommended energy savings, and conversely, a fee-bate is issued for buildings that perform above the recommended energy-saving measures.

Fee-bate credits reward passive solar design, photovoltaic solar electric, solar hot water, super-insulated thermal envelopes, whole-house ventilation using a heat recovery (HRV) system, and a low average U-factor for the windows.

Teton Heritage Builders makes sure they return fee-bates directly to homeowners, as Mark Dalby describes. “It comes off the permit costs and the county (or town) returns it to the homeowners’ hands. We find the added value to meet or exceed the construction standards will pay for itself with the fee-bate and additionally with lower operating costs for the lifetime of the home or building.”

Dubbe Moulder Architects sees proactively staying ahead of codes as part of meaningful, thoughtful design that supports the comfort and the safety of those who occupy the homes and buildings they design. However, the fee-bate system adds a good incentive.

“Geography is another challenge for building here. If Jackson Hole were located north of the Tetons, in Moran for example, we would have views with south-facing windows. Unfortunately, the majority of our views are north-facing, making efficient passive solar design difficult.”

–Mark Dalby, Partner, Teton Heritage Builders

“Geography is another challenge for building here,” begins Mark Dalby. “If Jackson Hole were located north of the Tetons, in Moran, for example, we would have views with south-facing windows. Unfortunately, the majority of our views are north-facing, making efficient passive solar design difficult.”

“Everyone wants views, which means glazing openings,” he continues. “While meeting the standards (30 percent window-to-wall ratio), we also want to use as much glass as possible. However, glass and window construction has evolved, and more clients are willing to extend the budget to cover triple-paned windows. Fortunately, the cost, for triple-paned windows, low-E glass, insulated glass, and similar products have become less expensive over the years and more attractive to our industry.”

Since homes function as systems, thermal envelopes and whole-house ventilation, as recommended in the fee-bate program, are closely related. Mark Dalby observes, “A tighter envelope with more insulation results in a tighter home that doesn’t lose heat. With our climate, these envelopes tend to trap in condensation. A fresh-air system provides continuous exchange of fresh air from the outside while exhausting stale, humid air. Heat recovery systems are able to salvage the majority of the heat from the air that is exhausted and transfer it to the incoming fresh air. These systems are very effective but add costs to building.”

HRV systems are certainly not a small expense,” agrees Chris Moulder. “But in Jackson’s long winters with super-tight homes, there has to be a fresh-air system, and without a heat recovery system, too much energy is lost.”

A continuous thermal envelope on the outside of a structure integrates insulation, structural sheathing, and vapor barrier. The benefits of thermal envelope systems as described by the Teton County Energy Mitigation Program are: faster to install, more quality control, a single-source responsibility for the warranty, ease of inspection, and long-term durability.

Eric Carlson, president of the Thermal Envelope Company (TEC), is leading the company’s growth in the Jackson Hole area. Until now, the company had been fulfilling clients’ needs throughout the Mountain West solely from Sun Valley, where the company was founded. TEC exclusively offers their Gen9 System along with all other types of traditional insulation.

“We’re a full-service insulation company. We deliver to the customer’s needs, offering traditionally designed building envelopes as well as innovative thermal envelope solutions, including the patented Gen9 System that improves thermal performance of any building. We are so confident that the Gen9 System will perform as promised, that we guarantee it.”

TEC’s Gen9 System is the ninth generation of an insulation system that engineer Art Carlson developed 15 years ago. “The goal is to stop the transfer of heat,” explains Art. “If you stop heat from leaving, and maintain it evenly throughout the home, the result will be a far more comfortable home. The Gen9 System virtually stops radiant and convective heat losses in addition to considerable reduction in conductive thermal bridging.” According to Art Carlson, the Gen9 system costs 15 to 40 percent less than comparable systems, and delivers 30 to 40 percent more energy efficiency and reduced energy consumption. As a result, TEC and their Gen9 System have garnered significant interest in the Jackson area.

Art points out, “The type of thermal envelope built into a new home is a permanent decision that has comfort, energy consumption, and economic consequences that will outlast the occupants. Solar and other extraneous energy solutions are changeable and adjustable as new technology comes along. So, getting the thermal envelope right the first time is critical to the long-term performance of a home.”

Thermal Envelopes

“The type of thermal envelope built into a new home is a permanent decision that has comfort, energy consumption, and economic consequences that will outlast the occupants. Solar and other extraneous energy solutions are changeable and adjustable as new technology comes along. So, getting the thermal envelope right the first time is critical to the long-term performance of a home.”

–Art Carlson, Thermal Envelope Company

Home Automation

“The industry standard has certainly moved to all systems being connected. “Now people want to receive reports: Is the water running? Who is at the front door? How much energy am I using, and have I reduced my usage? The reports are closely related to controls, and I think that’s another reason home automation is becoming so popular. The technology is available, and the ease of operation continues to improve.”

–Rich Ashburn, Owner, Jackson Hole AV

“Not so long ago the operation, maintenance, and repairs for homes were intuitive,” recounts Kurt Dubbe, “but gone are the days when we lay a multitude of phone lines and every light fixture and home entertainment device has its own on/off switch or remote. Home controls and automation are the fastest shifts driven by technology. Homeowners want to monitor and control their homes, and they want to do it remotely.”

“Yes,” Scott Schwab agrees, “the biggest advancement has been automation. It affects us as builders; even something like an ‘all off’ button affects early wiring. The majority of homes we build are second or third homes, and while homeowners want technology, they want to keep it simple with clearly understandable controls that are often similar to their other homes.”

“The industry standard has certainly moved to all systems being connected,” says Rich Ashburn, owner of Jackson Hole AV. Located in Jackson, Ashburn’s technology company specializes in home automation, integration, lighting control, window treatments, and A/V, including home theaters. They design and engineer systems, provide products, install, service, and continue support and programming as needed.

“Now people want to receive reports: Is the water running? Who is at the front door? How much energy am I using, and have I reduced my usage? The reports are closely related to controls, and I think that’s another reason home automation is becoming so popular. The technology is available, and the ease of operation continues to improve,” recounts Ashburn.

“Home controls and automation are the fastest shifts driven by technology. Homeowners want to monitor and control their homes, and they want to do it remotely.”

–Kurt Dubbe, Partner, Dubbe Moulder Architects

“Things are progressing fast. It used to be that people had a tabletop of remotes, and that has been replaced with apps on the phone. What’s coming (and is already here) is voice control. Alexa, Google Home, and Siri are all artificial intelligence operated by voice control.”

Rich Ashburn describes his own office. “When I enter and command ‘turn on the lights’, all the lights come on at the appropriate level for work stations, the music plays, and the temperature adjusts to our preferred setting when we occupy the office. Then, when I say ‘turn on meeting’, the light levels in the conference room adjust, the music lowers, and the television immediately sets for the correct input function for a presentation.”

“Similarly, in homes we design, ‘turn on entertain’ sets the lights, adjusts the shades, and turns on the TVs,” he continues. “Kitchens and bathrooms are the number-one places where people’s hands are full, and a voice command of ‘turn on my favorite music’ takes care of it, even from the shower.”

Returning to advances in building science, Ashburn says, “We can monitor not only internal temperatures that automatically adjust window shades, but also outside temperatures. Heat sensors in slabs of concrete sense differential temperatures and can predict changes in the outside temperatures to under-ramp or over-ramp the heat inside the home. Sensors also work with the fresh-air systems, and HRVs reach 80 percent efficiency in extracting heat from the exhausting air and heating the incoming air. Recently clients are requesting carbon dioxide sensors to tie into ventilation systems, as well.”

“Settings for when the home is occupied save considerable energy. Easy controls for home away or vacation integrated to the HVAC system sets the system to conserve when the home is unoccupied,” he continues. “People don’t want the same things, so we have the ability to individually write our own programs for the commands.”

He pauses and adds, “One area of home automation too important to overlook is the network. It’s the most complicated aspect in the industry. Every household and every individual has multiple devices, and there is a constant handshake between devices and the network where the devices are asking for information and it creates a network storm. It’s huge traffic, and when unmanaged, the network fails. The direction things are moving is that even more, everything, will be on the network. For that reason we install enterprise networks and anticipate higher demand on them in the future.”

Looking Forward

“Sustainability is in its infancy, and we are looking at just the front edge of challenges to how buildings perform. It is inevitable that the nation and world will become more serious about sustainability.”

–Kurt Dubbe, Partner, Dubbe Moulder Architects

It’s obvious that the improvements in how homes are built and operate are an investment. How will the economics play out in the future?

As far as the cost savings for energy, Mark Dalby answers, “The feedback I am getting is that comparing an older home designed with yesterday’s standards to a new one, the energy costs for the new home are half the cost while the new one is twice the size.”

Additionally, there is the issue of durability and whether the homes being built to meet and exceed standards will last longer. “While the upfront costs will be higher, we can build a quality home that will last many, many generations, and hopefully more,” answers Dalby. He notes that at this elevation and climate it is difficult to protect buildings against UV rays, snow, and freeze-thaw cycles. “We recognize that the exterior finishes will need to be maintained over the lifetime of the building and roof systems need to be maintained and/or replaced, as they have a shorter lifespan than the building.”

“The feedback I am getting is that comparing an older home designed with yesterday’s standards to a new one, the energy costs for the new home are half the cost while the new one is twice the size.”

–Mark Dalby, Partner, Teton Heritage Builders

And, does this longer life affect buyers’ decisions? “Not yet,” answers Dalby. “America is a young country, and unfortunately many of us have a stigma for short-term planning compared to, say Europe, where homes and structures are standing after a thousand years and being passed down from generation to generation. We will have to see if our mindset changes moving forward.”

Kurt Dubbe adds his thoughts about the future. “Sustainability is in its infancy, and we are looking at just the front edge of challenges to how buildings perform. It is inevitable that the nation and world will become more serious about sustainability.”

Artistry Draws on Technology

“Craftsmen and artists live for clients who want to do something different.”

–Bill Amaya, Owner, Beyond Wood

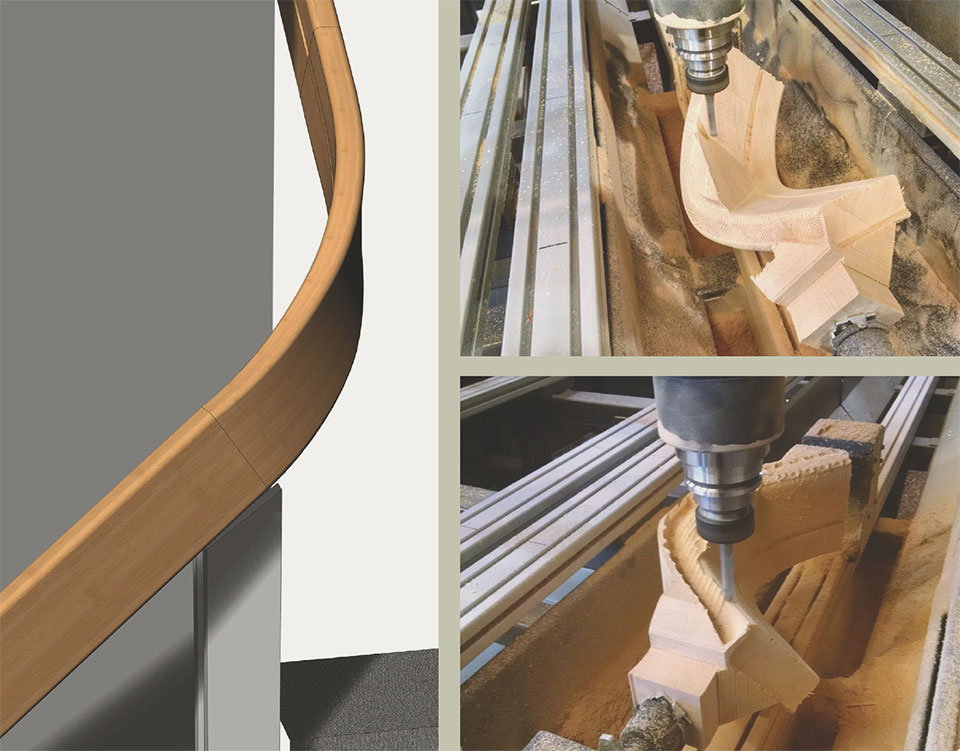

Watching Bill Amaya create a stairway is like experiencing a sculptor who knows his medium intimately. His hands merge his visions with the living quality of wood to create original, functional, and exacting forms. His roots are in old-world craftsmanship, and he takes his artful traditional skills forward by using the most advanced applications of 3D drafting and imaging technology, along with robotics.

“It’s a revolutionary change,” says Amaya, as he shows an intricate basket-weave pattern to be used as a ventilation grid. “I can create unique, one-of-a-kind forms and make them affordable and doable.” In an era where there are few skilled carvers and woodworkers at Amaya’s level, such a screen would normally take weeks of his time.

To enable him to create detailed carvings with precise dimensions, Amaya enlists a robot and operates it through programming he has developed. “It would not be possible without 3D designs and plans,” he explains. Amaya’s woodworking robot can work along five axes and ten directions: up, down, right, left, in, and out, plus the robot can modify the angle of approach right and left and rotate clockwise or counterclockwise. Through programmed commands, the robot can change bits, cuts, and rotation. “While it would take many, many years to train someone to carve at this level, I can train someone in a much shorter time to work the robot.”

One of the biggest benefits Amaya has discovered of the 3D programs is team collaboration through screen sharing. “Aesthetics are very important, and I can work with homeowners, general contractors, architects, and interior designers through screen sharing where I present 3D images of the design. They react with their ideas of how we can improve it, and I can modify the design as they watch. They can view designs from all angles, as well as seeing how one aspect will fit in with the whole.” This screen-share collaboration process allows Amaya to work with anyone around the country or around the world. “And the work is the finest quality,” Amaya adds. “Working in 3D design is working in reality.”

Amaya’s company, Beyond Wood, builds cabinets, stairways, and handrails, but it is much more than a cabinet company. As his reputation grows, he is also sought-after for design and digital fabrication, especially troubleshooting complex jobs. He offers a story of a recent commission. “I was approached to replace some leaky windows. The window design was curvilinear, the wall protruded along yet another series of curves, making the windows double-curved. I recorded dimensions with my digital measuring device, drew 3D plans, and sent them to the manufacturer in another state. I created the wooden window frames and verified that the dimensions of the delivered glass were correct. The installation for 60 windows went perfectly, and my frames and the windows fit exactly, error-free. Without 3D plans and images, I don’t think it could ever have happened!”

Amaya finds that clients respond strongly to 3D plans. “Many of us in the construction trades have over 20 years of experience reading two-dimensional plans, but understanding and visualizing plans are difficult for homeowners. They react strongly to seeing their homes in 3D and it connects them and inspires them to go be creative and innovative so that their home becomes even more personal and closer to their aesthetics. Craftsmen and artists live for clients who want to do something different.”