Custom Steel & Customer Service

by Danielle Vigueria

“Steel seems limitless to me,” says Cody Hawes, owner of Simply Fabricated, located in Bend, Oregon. “There are some things that other mediums just cannot do, but for me, steel has infinite possibilities.” After attending the Art Institute of Portland, Cody realized early on that his artistic expression might take a less traditional form when he fell in love with fabrication.

After several years working as a welder for Fortune 500 metal fabrication companies, in 2016 Cody followed his entrepreneurial spirit and opened Simply Fabricated (SimFab). Since then, the company has earned a reputation for being one of the area’s premier custom metal fabrication businesses. And Cody has been working hard to become a one-stop shop that meets all of the structural and aesthetic steel needs of the homes in Central Oregon.

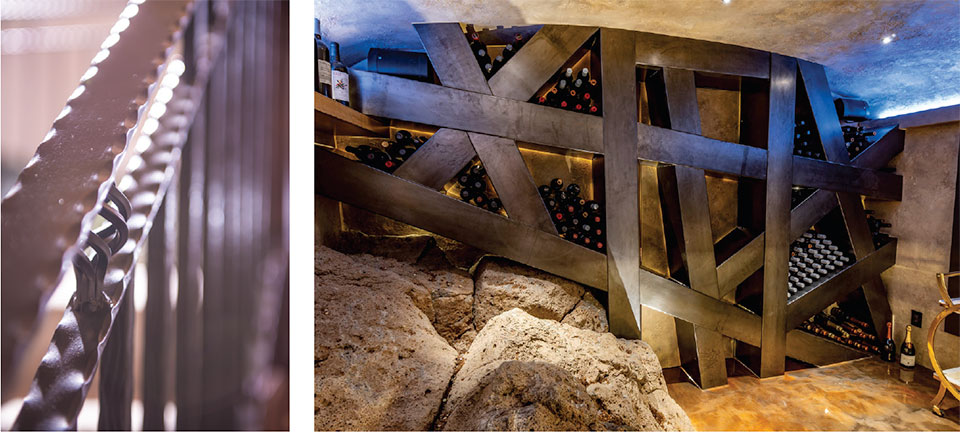

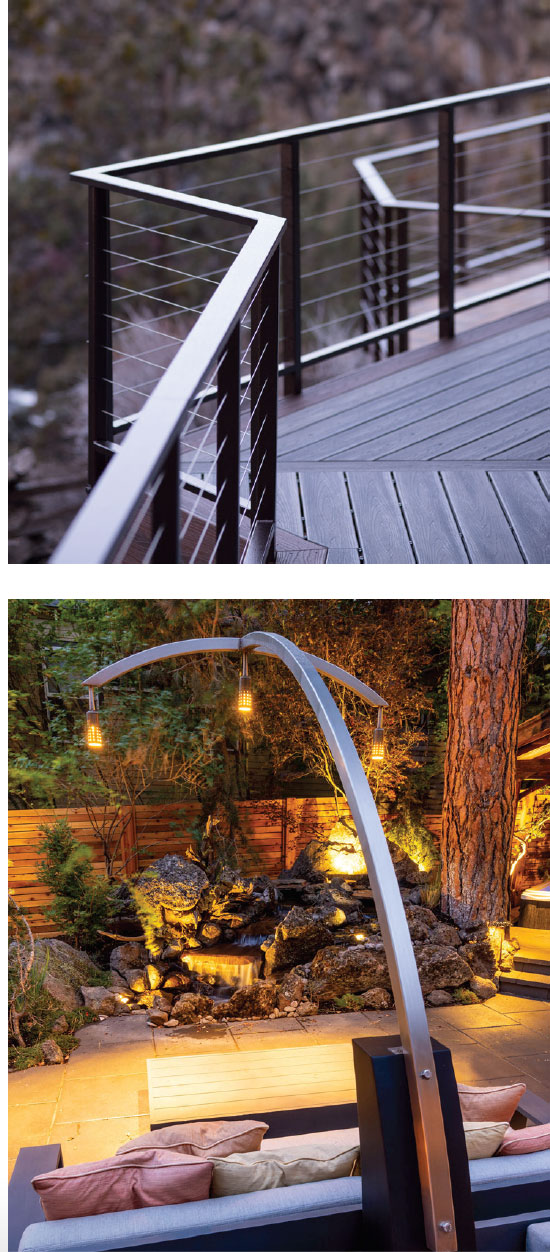

Known for impeccable quality, SimFab can do it all—from full-scale wine cellars and massive ornate gates, to sleek steel stair stringers and sturdy railings. “My motto is ‘Your Dream, My Design, Our Creation,’” says Cody. “We can deliver just about anything our clients can imagine. Structural architecture or purely decorative elements, we can take a pile of steel and mold, shape, and weld it into a masterpiece.”

“There are some things that other mediums just cannot do, but for me, steel has infinite possibilities.”

–Cody Hawes, Owner, Simply Fabricated

“Right now, we are working on a whole-house project in Brasada Ranch,” Cody continues. “It will include a structural steel package, exterior and interior steel stairs, a large water feature, a courtyard gate, and several other pieces. It is really exciting for me to see so much of our product in one house. And to have so much trust from the owner and builder.”

With the endless applications and considerations, each project SimFab takes on truly is a custom endeavor. And in a world of automated manufacturing systems, Cody and his team of full-time fabricators are still getting their hands dirty; measuring, designing, cutting, and installing. They expertly employ specialized formulas and processes to create stunning patinas, intricate artwork, and detailed finishes that require the talent of skilled technicians to achieve.

To further enhance the business’ capabilities, SimFab recently developed an in-house, full-service wood shop. This new addition will allow them to produce any wooden components or accents that previously would have been supplied by a finish carpenter. Gate slats, caps for guard rails, tread for stairs—whatever needs to be integrated into a SimFab steel project can now be made onsite.

“Being able to make our own wooden elements will give us more ownership in the design, quality, and timelines of our projects, which will ultimately allow us to provide even greater customer service to our clients.”

–Cody Hawes, Owner, Simply Fabricated

“This is a great complement to our business,” says Cody. “Being able to make our own wooden elements will give us more ownership in the design, quality, and timelines of our projects, which will ultimately allow us to provide even greater customer service to our clients.”

Delivering that level of exceptional customer service is a company priority that the SimFab team follows through on every day. Phone calls are returned. Honesty and integrity guide their work. And relationships are built on trust. “We believe in producing the highest quality product possible, but we also believe in taking care of others,” says Cody. “Our mission is to facilitate lifelong customers. Customer service, craftsmanship, and communication are key. I focus on being the best steward of my clients’ time and serving them so well that they want to come to us any time they need something.”

And right now, Cody says there are a couple of trends that clients are asking for, including a growing demand for cladding, the process of installing steel sheet metal to the interior of a fireplace’s walls. Rather than the former in-demand aesthetic of stacked river rock accenting fireplaces, more clients are looking to incorporate blackened patina steel with elaborate trim and faux rivets to add a more refined, decorative touch.

Another frequent request is floating stairs. For remodels and new builds, steel-suspended staircases are opening up living spaces and eliminating boxy interior walls and blocked views. And with the Pacific Northwest’s emphasis on outdoor living, fire pits of all shapes and sizes are always a sought-after item.

“Steel is extremely functional, but at the same time it can be used to add beautiful aesthetic touches to a home as well. The art of creating with so much flexibility and the satisfaction of seeing the final product, that’s what motivates me.”

–Cody Hawes, Owner, Simply Fabricated

Along with custom work for local contractors and homeowners, SimFab is also translating their enhanced capabilities and focus on service into the development of a direct-to-consumer product line. They hope to continue to expand their reach by building and shipping beautifully crafted live-edge tables, benches, hall trees, and other furniture pieces that feature a mix of steel and wood across the country.

“We are excited to provide such a diverse spectrum of steel solutions to our clients,” says Cody. “Steel is extremely functional, but at the same time it can be used to add beautiful aesthetic touches to a home as well. The art of creating with so much flexibility and the satisfaction of seeing the final product, that’s what motivates me.”