For almost a century, little has changed in the way homes have been built, but now, building science is leading homebuilding into a new era.

A hundred-year-old or more Craftsman or Victorian home might seem a normal sight in today’s neighborhoods. However, how normal would a Model T or horse and buggy look? Technology has driven transportation incredibly far forward, so much so that people can identify the age of a photo by cars, and a new Tesla easily announces today’s date. Homebuilding has eluded dramatic technical advancements—at least until recently.

Preston Campbell, owner of Go West Development in Park City, came into home construction from a high-tech background in software development, and he is attuned to how technology and new thinking can improve the homes he builds. “A car today versus one 20 years old is safer, faster, more energy-efficient, more comfortable, more reliable, and lasts longer. Comparing homes, you can’t see many improvements, except for perhaps slightly more energy efficiency. But, building science has made giant leaps forward and much more is possible than ever before. At Go West Development, we are building far more advanced homes than codes require and using current building science to make them more energy-efficient, more comfortable, and longer-lasting. But this is a big step for people building new homes because, frankly, the codes are lagging behind.”

Glenn Taucher and Matthew Tracy, professionals with the design firm Line 8 Design in Salt Lake City, design custom high-end residences. Both are in agreement that the science is here and they can design systems in structures that push thermal envelopes and enhance performance. “We have the knowledge, we can design homes that are better, but there is backlash from pricing,” says Taucher. Tracy agrees, “There is a downward pressure on cost, despite the technical feasibility.”

Jason Ledyard, president of Ledyard Homes in Park City, is also in agreement. Prior to building predominantly new high-end resort homes, he contracted for numerous remodels in the area and questioned what he had to tear out and why. Most often, the culprit was moisture damage. His background in engineering and commercial construction motivated him to rethink how he could more responsibly and economically serve his clients while at the same time minimize effects to the environment. “I am confident that at the top end of the market, we can build better custom homes that perform well and that ultimately make more economic sense,” he asserts. “The ultimate goal is to bring this technology and improved building practice to all segments of the market, just as we’ve done with air bags and stability systems, once only found in expensive luxury cars.”

“Building science has made giant leaps forward and much more is possible than ever before.”

—Preston Campbell, Go West Development

New Home Building Dilemma

Builders, architects, and specialists now can build better and longer-lasting homes because of the advances in building products, techniques, and testing. However, building codes are not yet mandating these advances in building science. It puts people building homes in an interesting position as they dialogue with the pros on their teams. Questions arise that aren’t easily answered. It costs more to build with advanced practices, so is it worth it? What differences will spending the extra money make to the comfort of living in the home or operating costs like utilities and maintenance? And the biggest question: what happens when it is time to sell? Can the money be recovered? Will others see the value?

Park City builder Preston Campbell acknowledges that these are difficult questions for those building a new home. For a perspective, he suggests looking north to Canada where the codes demand far more. “The Canadian code with standards for fresh air exchange, drainage planes, U-values for windows, and R-values for walls are 20 years ahead of here,” says Campbell.

A side benefit to the Canadian standards is that new products have been developed to meet the standards and they are already on the market here. In the U.S., builders like Campbell and Ledyard can obtain the new products and build here to similar standards as required in Canada.

The future of local codes is unknown, which makes it a difficult issue for builders who wish to do the most responsible thing for clients today. “It could be very interesting here if, in the immediate future, third-party testing is required and if new standards that we see possibly coming are codified,” says Campbell. “Many, perhaps most, of the homes being constructed today would fail to perform, especially in terms of fresh air exchange and wall assemblies’ ability to dry. I fear it would drive down the resale values. Our company is building homes today that will meet future standards and be livable well into the next century and beyond. We see it as building responsibly and looking out for our clients’ investments.”

However, Campbell admits that future-proofing homes comes at a cost. Until the issue of the gap between best building practices and what’s required by codes is worked out, there will continue to be a dialogue between builders and clients about how far they want to go and how high in the budget they are willing to reach.

Jason Ledyard can document energy savings and recovered costs from downsizing the size of components of lighting as well as heating and cooling systems. It is, however, too early to demonstrate how the long-term durability of the homes he builds will pencil out in lower maintenance and higher resale values. “I feel responsible to minimize impacts while still meeting the desires of the owners, so it will continue to be a balance between what is most responsible and technically and financially sound.”

Matthew Tracy observes that while the codes do not require it, new building science measures have incentives. In Utah there are market mechanisms as a result of government and private industry partnerships. “Rocky Mountain Power offers rebates for taking pressure off the grid,” he explains. As for the clients, Tracy says, “Some do it because it is the right thing, but others will refuse the extra measures because they want the home to fit in the budget.”

Glenn Taucher adds, “We try to always do things financially responsibly. However, sometimes the discussion or analysis neglects what can become of the house. Tiny steps now make a difference in the longevity of the home.” He indicates that the science hasn’t been around long enough for tools to be developed that measure the true cost/benefits, especially if the measures make homes last much longer. “As the governmental agencies make changes to the building code, this will really propel improved building practices across the board.”

“It could be very interesting here if, in the immediate future, third-party testing is Required and if new standards that we see possibly coming are codified. Many, perhaps most, of the homes being constructed today would fail to perform, especially in terms of fresh air exchange and wall assemblies’ ability to dry.”

—Preston Campbell, Go West Development

For more information, please visit us at Go West Development

Providing Fresh Air

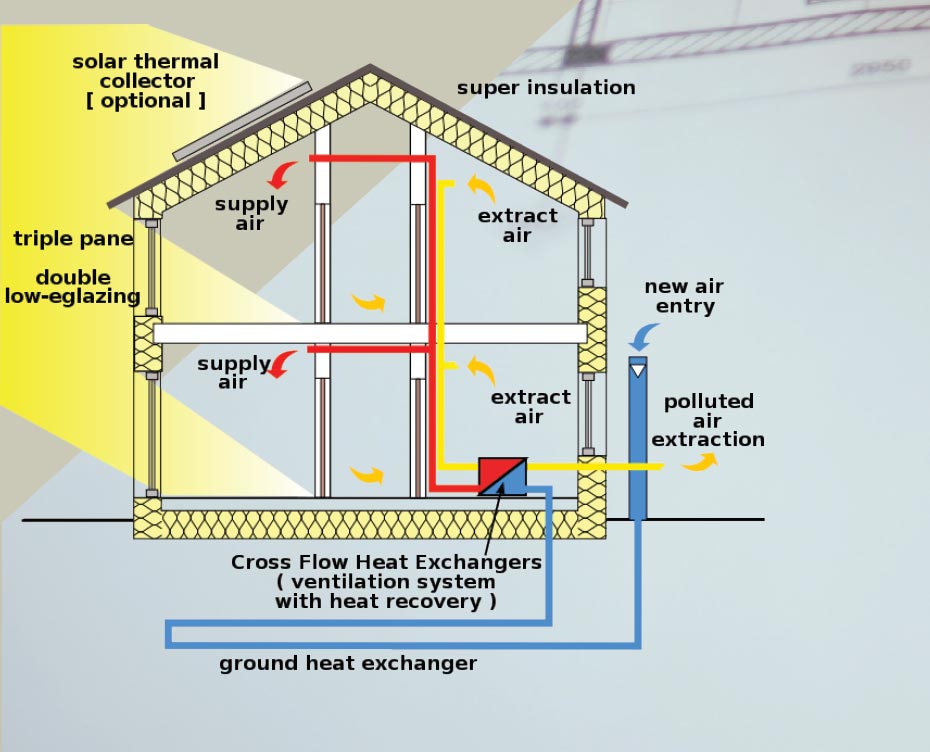

To better understand some of the new advances in building practices, it’s helpful to look back to the 1970s and 1980s, when fuel shortages initiated efforts to save energy. As a consequence, homes and commercial buildings were better sealed and insulated to prevent wasting the energy used for heating and cooling. Despite good intentions, problems emerged from sealing and not exchanging the air, like sick building syndrome. That means that a cold, drafty Victorian home had winds gusting through and never felt warm, but along with those uncomfortable drafts came fresh air. Tightly constructed and well-insulated homes, such as those we have in Park City, need some help. As an adage in the building science community goes, build tight and ventilate right.

“An air exchange system is the best current technology to eliminate condensation on windows and keep the home refreshed with clean air.”

–Matthew Tracy, Line 8 Design

Matthew Tracy from Line 8 Design says, “There is excellent technology to create systems that make even the most air-tight homes breathable. An air exchange system is the best current technology to eliminate condensation on windows and keep the home refreshed with clean air.”

Preston Campbell puts it bluntly, “You can’t live without fresh air. In many houses being built today, carbon dioxide levels go up, oxygen levels go down, and common products that make up our lives give off unhealthy gasses.” With concerns about off-gassing and VOCs (volatile organic compounds), there have been efforts to produce alternative products, but Campbell does not see these as a substitute for a good fresh air exchange system. “Low VOC paints and similar products are overrated, because there are other sources of unhealthy air—even clothing off-gasses. The big challenge remains to get fresh air into the house and stale air out, but to do it in such a way that the walls stay dry.”

Campbell continues, “Fresh air exchange is essentially a math problem to provide as much fresh air as needed per hour. This is accomplished by properly sizing the HRV (heat recovery ventilator) to bring the correct amount of fresh air in and to do it while warming it up for free using the heat from the stale air you are expelling.” As he explains, HRVs are a big step in making living in a home with air exchange comfortable because the HRVs bring the temperature of the incoming fresh air to the desired temperature. Little energy is lost, as the system recovers the heat from the stale air that is exhausted.

For more information, please visit us at Line 8 Design

Managing Moisture

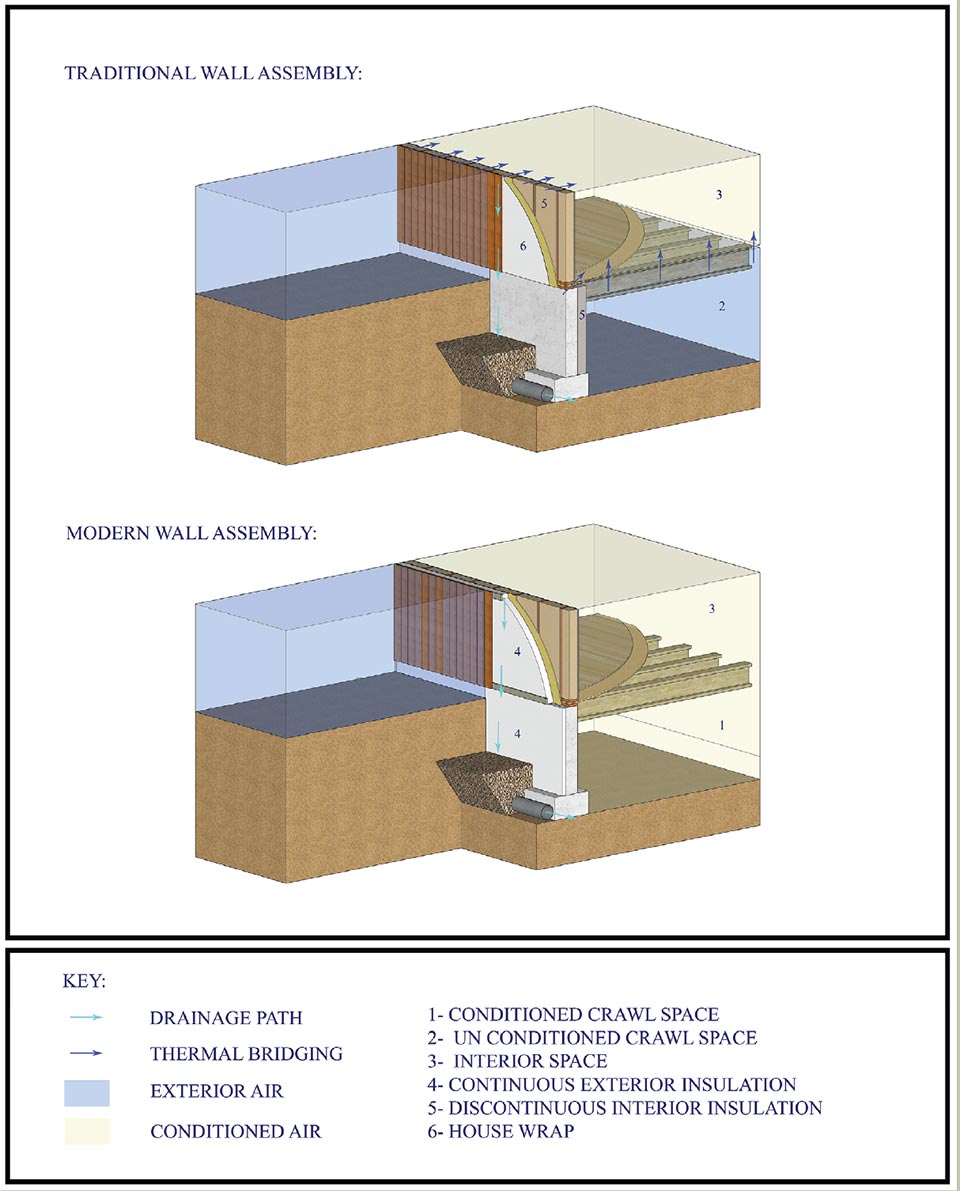

Preston Campbell introduces the concept of moisture control by saying, “We know that all walls get wet; the trick is to give them a way to dry.” Moisture control systems are closely related to the same causes that generate the need for fresh air exchange systems. Preston Campbell reflects, “In the 1980s, we built houses tighter using rubber that doesn’t let walls and wood breath. We learned that it was unsustainable and leads to a short life span of the home, and we now know that moisture control adds longer life.”

“Whenever there is a big opening in the wall, like for doors, windows, or fireplaces, There needs to be a drainage plane around the opening to divert the water.”

–Jason Ledyard, Ledyard Homes

After observing the moisture damage in the buildings he remodeled, Jason Ledyard went on the hunt for a better way to build than with the traditional polyethylene house-wraps common in both residential and commercial construction. “Two years ago I started applying a sprayed vapor barrier instead. It was a consequence of looking for failure modes, part of my training in engineering. With traditional house-wraps, tears and nail holes are inevitable, and they leak. This new vapor barrier goes on like paint in a very cost-effective manner. In fact, it is easier to apply than TYVEK and similar house-wraps. It bonds better to wood, seals around nails, and lasts longer than wood. The material is not too environmentally unfriendly, and there is no waste in its application. Vapor barriers keep wood dry by allowing water vapor to move out through pores, but it does not let drops penetrate.”

By building first in Ohio and the Midwest, Jason Ledyard became well aware of the damage possible from rain and humidity. “Whenever there is a big opening in the wall, like for doors, windows, or fireplaces, there needs to be a drainage plane around the opening to divert the water. We rely upon flashing systems integrated closely with the vapor barrier; the key is how they lay up together so the flashing bonds permanently with the vapor barrier.”

“We rely upon flashing systems integrated closely with the vapor barrier; the key is howthey lay up together so the flashing bonds permanently with the vapor barrier.”

–Jason Ledyard, Ledyard Homes

The other concern is condensation. The warm, moist air that feels good inside the home cools off in the walls as the outside temperatures cool, and water forms in the walls. Ledyard describes that another layer of insulation is necessary to prevent humidity from condensing. “After the electric and plumbing are complete, we apply two inches of closed-cell foam inside all the walls and four inches in unvented attics. Done properly, condensation is unable to take place.”

Insulation is key to many of the building science improvements. Go West Development uses rigid foam insulation with breathable membranes, and Preston Campbell remarks, “We put in twice the insulation that codes require.”

Heating Keeps Improving

Glenn Taucher observes, “Radiant heat is the most efficient and sought-after. I would say that 99 percent of our homes have radiant heat. For comfort, we supplement with forced air. The house is zoned by solar orientation, so some zones run cooler and others warmer. The forced air supplementation adjusts the temperatures in these zones. Also, as individuals, we don’t all feel temperature the same way. By designing the forced air systems with sensors and thermostats in rooms, the adjustments respond to the needs of personal comfort.”

Matthew Tracy is watching ICE cooling systems. Now found in commercial buildings, the technology allows for nighttime off-peak energy to provide cooling during the day.

Asked about advances in heating systems, Campbell says that he combines radiant heat with destratification fans for heat distribution to eliminate cold and hot spots. He notes an important advance, “Lower temperatures for floors is one of the most important ways to make radiant heating systems more efficient. We reduce the water temperature to 90 or 100 degrees from 140 degrees for far greater efficiency, and dew point sensors allow us to use floors for cooling without the risk of moisture in the air condensing onto the floors.”

Jason Ledyard notes that with more and proper insulation, ERV (energy recovery ventilation), and designing an efficient but smaller-sized cooling system, the energy savings pay for the upgrades within 10 years.

Daring New Designs

Jason Ledyard says that the homes he is building now in Park City are more complicated than low- and mid-rise commercial, which he has built before. “It’s been driven by the architects predominantly after the downturn. They are designing big steel structures to provide for views and big, open floor plans to serve as large comfortable gathering spaces for friends and family.” He adds that the desire for more natural light and views means more glass, both in windows and doors, and definitely the new products on the market make a difference. “Bigger panes of glass, more energy-efficient assemblies, and better U-values mean that we can build more efficiently than in the past with glass.”

Preston Campbell has a similar observation. “In Park City, we are building bigger and more complicated homes with more steel, more cantilevers, flat roofs, greater expanses of glass, fewer walls, and less wood,” he says.

Matthew Tracy speaks to this from his designer’s perspective, saying, “Steel and concrete have always been there as materials, but in recent times clients are pushing us to see what’s possible, and they want a lot of glass in these homes and broad spans that require steel.”

However, both Matthew Tracy and Glenn Taucher find that clients are now requesting smaller homes more often than in the past. “When I began in Aspen,” Tracy recalls, “there was not a home that was too big to build. Now, clients more frequently want smaller homes. There’s room to snuggle seating closer to the views, and I find I can put the poetry back into the home.” He adds that the downsizing places less pressure on technical solutions for performance and is a downward pressure on cost. Taucher’s observation is that ten years ago, 11,000 to 20,000 square feet was common, and now “the magic number is around 5,000 square feet. We’re also seeing some clients request solar and geothermal active energy systems in addition to the passive solar components we always include in designs.”

Bottom line, new designs are possible with the advances in building science, and the shifts in home design have pushed materials and construction. The interplay pushes contractors’ building skills and techniques, and the contractors challenge home designers to create more complex designs. The result is a leap since the millennium in home quality, complexity, and dramatic design, but it leaves consumers with some difficult decisions as to whether they should pursue the advances and count on financial rewards in the future rather than budget savings today.

For more information, please visit us at Ledyard Homes

Home Automation Systems Part of Advances in Building Science

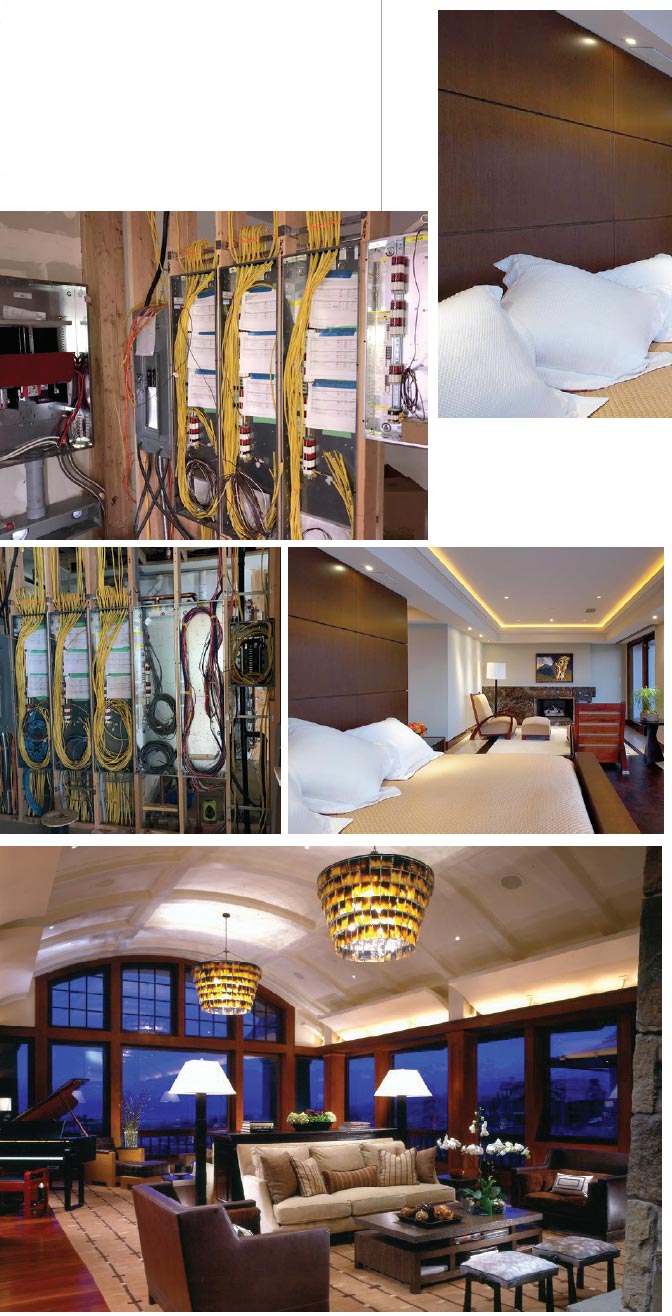

It is interesting that when professionals make electronics and automation work well, we don’t notice technology. Not demanding much of our attention doesn’t diminish the important role that electronics play in the easy management and efficiencies that building science has introduced into homes. Glenn Johnson is the face of home technology to many national clients, as a lighting and systems architect, inventor, author, lecturer, and owner of Park City’s Adaptive Design Group. He takes time to explain the newest technologies in homes.

whj : What have been the changes in automation to help save energy in homes over the last 20 years?

Glenn Johnson: Energy savings depend on the level and quality of the automation system. For example, most custom homes in the last five years minimally have adopted energy-saving LED lighting and automated dimming controls. Initially, these two elements add to higher costs for fixtures and equipment, but they are easily paid back in three to five years in energy cost savings. Home automation and management elements like temperature controls, water flow, and electricity management are important for overall savings, but I find that few architects and builders brief homeowners in the technology. There is excellent hardware to select from, but it takes seamless software communication and experts in design and installation to coordinate and piece everything together.

whj : On that subject, how does automation provide monitoring and controls for heating systems we have been talking about with radiantheating, cooling, and fresh air exchange?

GJ: A full home automation system incorporates heating, cooling, fresh air, radiant floors, and motorized windows and window coverings, but it takes forethought, coordination, and planning. Perhaps the only time all of the build disciplines are in the planning room together is when there is complete design coordination for the automation systems between the systems designer (like me), integrator, architect, electrical and low-voltage contractor, mechanical contractor, plumber, and general contractor. The meeting results in full drawings, including all controllable equipment, connectivity, user interface wall devices, and sensors, as well as a division of installation labor that must be defined up front. Properly executed, the home is automatically set to the predetermined temperature levels according to the owners’ wishes. Wall controls add a degree of flexibility, but largely the entire system is pre-set to call on heating and cooling based upon the room temperature sensors for keeping the home comfortable. Without a clear idea about what temperatures the client wants and a meeting to sort out zones, homeowners will find it frustrating to find the right settings. Best to solve it in advance.

whj : How does technology know how well systems are performing?

GJ: Home integration systems on a wired network are constantly monitoring the use of the home and reporting any faults on all systems. Other than the initial set-up and testing of all systems, the network monitoring does the rest. Good reporting, immediate response to critical data, and boots on the ground lead to homeowners’ comfort.

whj : What technology can we expect in the future for advanced homes?

GJ: I have mentioned wired networks a few times. The future-proofing of any home will require hardwired network cable, Cat6, throughout the home to a hub location. With large amounts of data and technologies that are flowing to the home, the Cat6 backbone coupled with a secure network are the sure keys to success. Wireless plug and play DIY systems should not be expected to be the end-all to energy savings, swift data transfer, and full home automation.

For more information, please visit us at Adaptive Design Group