Families working in business together have a long tradition that is evolving into new dynamic partnerships as they discover what it takes to work successfully together, both in the business world and at home.

While the Ma and Pa Corner Store is largely a thing of the past, that doesn’t mean there is a decline in family-owned and -operated businesses. On the contrary, family businesses continue to be important cornerstones of the economy, and that extends to the luxury home industry. Building upon the trust, communication, and core values fostered at home, families are creating businesses that rely not only on these commonalities but also upon each family member’s diverse talents, skills, and training.

90 percent of the nation’s businesses are family-owned or controlled. And family businesses provide half of the jobs in Europe and America.

Statistics speak to the importance of families in business together. According to the U.S. Census Bureau, 90 percent of the nation’s businesses are family-owned or controlled. And family businesses provide half of the jobs in Europe and America, according to Ernst & Young. Starting a family business is a daring thing to do, as during the early years family members sacrifice by working for free or at a lower rate than the external job market would pay for similar skills (Jennifer Xue, Silicone Valley Globe). However, as these local Park City businesses say, the rewards of working together are worth the challenges.

Adaptive Design: Lighting Design & Innovation

Glenn Johnson was born into a family of early lighting professionals, and quite literally, he has written the book on lighting design. Since 2013, Glenn and his wife Charlene have made their home in Park City, a long-time dream now realized, and their Park City office is only seven minutes away from their home. Adaptive Design Group, Inc., a full-service design and engineering firm, provides lighting design, lighting control engineering and programming, electrical design, and full electronic systems design (audio, video, security, and secure home networking through a single controller) for large custom luxury home projects throughout the Mountain West and the country. Glenn’s three sons, Chris, Scott, and Matt, have joined the firm and each contributes a specialized skill to mark yet another generation in the business. His wife Charlene joins them in the office and assists with marketing materials.

“My father, Merlin E. Johnson, invited my two brothers and me to join Artistic Lighting & Electric, his electrical contracting and lighting design firm in the San Francisco Bay Area,” Glenn recounts about his early years. “I became a journeyman electrician, and we worked on the most exclusive homes in the area and became early pioneers in lighting design before there was a course of college studies or even a title for the profession. I followed my father to his Palm Springs, California office, and after my marriage, I opened my own business in Los Angeles, Lighting by Design. In eight years, we had projects in the exclusive areas of Beverly Hills, Bel Air, Malibu, and Santa Barbara, and many were for major figures in the entertainment industry. However, a project in Alpine, Utah, made me start thinking of relocating to Utah for its fresh air, four seasons, limited crowds, and great place to raise a family.”

“A project in Alpine, Utah, made me start thinking of relocating to Utah for its fresh air, four seasons, limited crowds, and great place to raise a family.”

–Glenn Johnson, Adaptive Design Group, Inc.

After a stretch of working both in California and the Intermountain region with his own firm, Glenn Johnson joined Spectrum Engineering in Salt Lake as a partner, and during his ten years with Spectrum, the firm grew significantly from 12 to 85 employees. During this time Glenn wrote The Art of Illumination: Residential Lighting Design, a textbook on lighting design used by 25 colleges and universities. He left Spectrum and established Adaptive Design Group, Inc. in 2002.

“In addition to working on exclusive homes across the U.S., I also launched a lecture series through colleges, universities, and trade groups.” Glenn recalls. “About this time, I started thinking about the future of the business, and like my father, I looked to my boys. Family business is a natural progression: my father, his father, and my grandmother’s brothers all had their own businesses of various kinds. Also, there was the issue of loyalty and retention. I have trained so many who have gone out to start their own businesses and ended up competing against me, so I was inspired to put the effort into developing the talents of my sons, instead.”

Christopher, Glenn’s eldest son, eased into the business by studying AutoCad in high school and working after school with Adaptive Design’s designers and engineers and then earned his degree at Boston Architectural College in architectural design. He returned to Utah in 2017 and works with brother Matt on project plans, and he develops lighting plans and final specifications.

Matt, the youngest of the three sons, works with designing the keypad controls and coordinates with contractors in addition to project plans. Matt similarly mastered AutoCad while in high school and worked in the family business before studying physics in college. He is certified in advanced lighting controls.

Scott joined the firm in 2007 and takes charge of the website, social media, and marketing in addition to managing the Merlin Light product, a lighting invention used to illuminate artwork developed by Glenn’s father. Additionally, Glenn and Charlene have two daughters, Carly and Sara, who are just finishing their education and haven’t yet decided on a career path.

The family gets together often to enjoy music, golf, and snowboarding. “They are great activities because we focus on what we are doing and don’t talk business,” says Glenn. However, he admits that it is difficult to leave the business for too long or go too far away.

Glenn finds that clients appreciate the family business nature of Adaptive Designs. “The focus is all about continuing to build the best practice and to provide the best service to clients. No one steps on another’s toes, no one is positioning for the other’s job, and no one is trying to steal clients and start their own firm or to take intellectual properties. Most of our clients are astonished at our ability to work together so well. For me, I can focus on the work and not worry about the dynamics around me, and I find great pleasure in seeing Christopher, Scott, and Matt grow in their proficiencies and take over more and more of the responsibilities.”

“The focus is all about continuing to build the best practice and to provide the best service to clients. No one steps on another’s toes, no one is positioning for the other’s job, and no one is trying to steal clients and start their own firm.”

–Glenn Johnson, Adaptive Design Group, Inc.

Matt Mullin & Katy Patterson of the Lange Group

“We were the classic annoying younger sister and bossy older brother.”

–Katy Patterson , The Lange Group

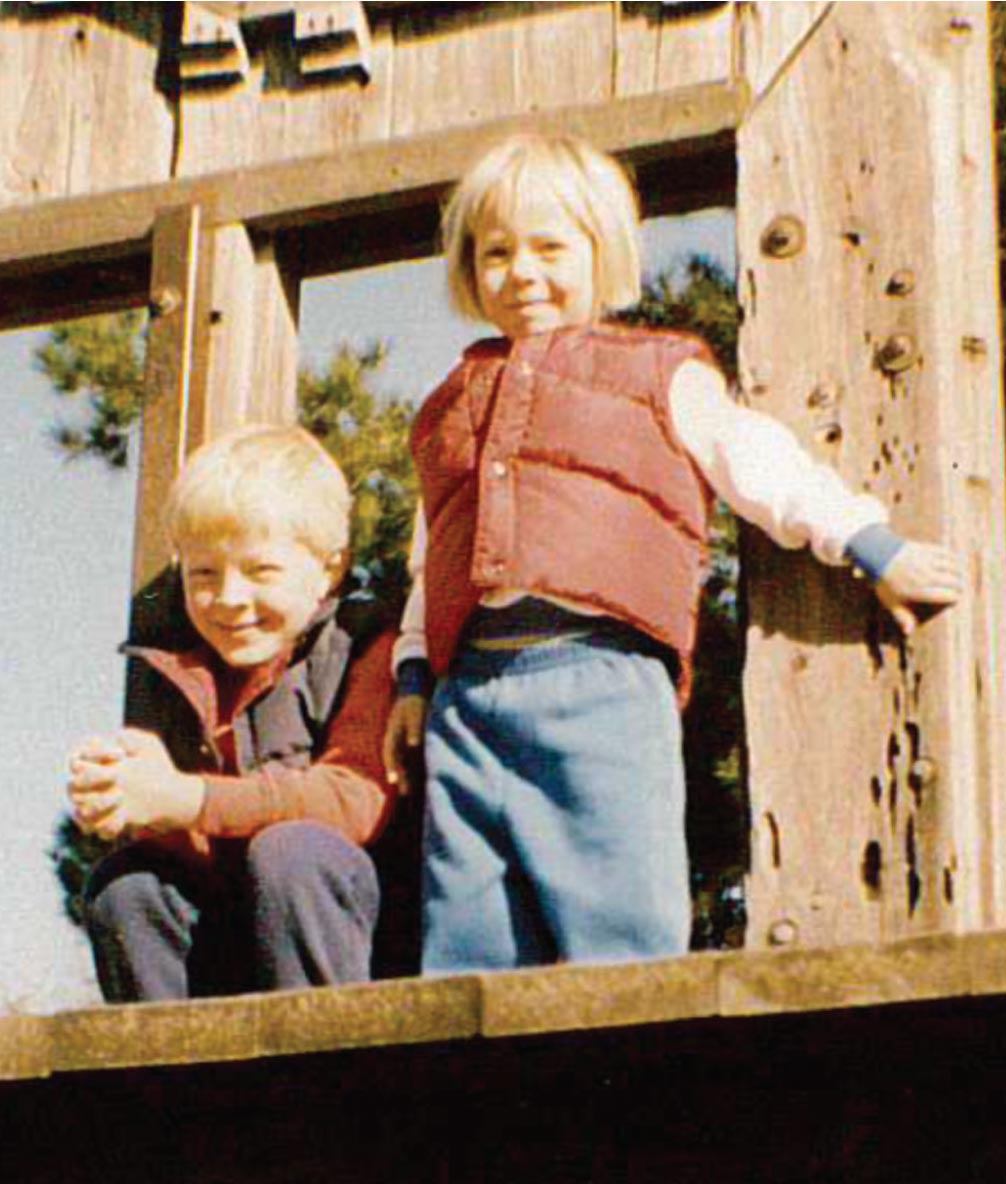

Growing up skiing together in Vail, Colorado, brother and sister Matt and Katy Mullin (now Katy Patterson) could not have predicted that in the future they would be working closely together on a daily basis in the same real estate brokerage. They also couldn’t predict that they would enjoy watching their children growing up together in a ski town like they did. However, their roots, as they describe them, suggest an early influence in their future direction. “We’re two and half years apart, and our parents first worked as ski instructors and then went into the home industry. Our mom was a real estate agent and our dad worked in construction and home inspections,” Matt tells. Katy adds, “We were the classic annoying younger sister and bossy older brother.”

Their paths diverged with college. Matt studied international business at Pepperdine and finished just in time for the business slowdown following 9/11. His opportunity came from a close family member who invited him to join him in Park City to be a part of Ironwood Development, a property development firm that continues to make a mark with its high-level projects. “I had been to Park City many times for ski and bike races ” recalls Matt. “But it was on a ski trip during high school that I had the opportunity to meet Will Lange, with whom I now work.”

“We were raised with the same traits.”

–Matt Mullin , The Lange Group

Katy had just graduated from the University of Colorado in Boulder when she, too, was asked to join the Ironwood Development team with Matt. “I knew Katy would be a good fit. We were raised with the same traits. She is fair, honest, reasonable, and competent. Plus she has her own strengths. She is a natural communicator and excellent listener,” he says. True to Matt’s prediction, they work together well. For five years they went their own ways, but both stayed in Park City and headed into residential real estate. First Katy got her real estate license, and then Matt. Matt was buying out Will Lange’s real estate sales business and invited Katy to join them and be part of the team at Summit Sotheby’s Park City.

“We really knew what we were getting into and had realistic expectations of the demands of working in real estate,” Katy tells. “We had learned from observing at home that it requires detailed knowledge for the negotiations and a great deal of patience.”

And how has it been to work with her big brother? “First and foremost, we have a ton of respect for one another, and we genuinely care about each other’s individual success. We have a business plan, but we kept the expectations for our relationship informal. We know how our actions can affect our individual families both positively and negatively,” Katy explains.

Matt says, “For clients, the family connection is a benefit. They know we have backup, and they sense the quality of our values.”

Katy agrees and adds, “Buying and selling residential real estate is rooted around family. People are making decisions on behalf of their families with long-term decisions and planning, so our clients are assured that we understand what’s on the line for them. And, they are right; we get it. They see that we are running a family business and sense our work ethic. We have our clients’ best interests in mind, and we are looking out for each other. That attitude results in success for everyone.”

As brother and sister, working together benefits from their similarities as well as their differences. In addition to the similarities they share, Katy mentions one more point, saying, “There is no room for ego in this business, and we both manage to leave it out. It’s not about us; it’s about doing a good job for our clients.” Katy sees that their skills balance well. “Matt is very analytical and skilled with figures. He also brings in great leadership, and he is very involved in our local community,” she explains.

“We really knew what we were getting into and had realistic expectations of the demands of working in real estate.”

–Katy Patterson , The Lange Group

Matt says of Katy, “She is detail-oriented and strives for proper execution. Also, she has the ability to find balanced solutions and knows how to compromise. I’m also impressed with her ability to speak directly and kindly when someone needs to hear the truth.”

There’s a downside and upside to working together. “The disadvantage is obvious. We can’t get away and take a vacation together even though our children are similar in age and it would be fun. But there are advantages: we have a deeper bond and relationship, we get to know each other better, our children get to know one another well, and when the kids are sick, there is no question of helping the other out. There is perhaps a freer flow of information, and we feel comfortable trusting and relying upon each other. We’ve got the other’s back,” says Katy.

Matt adds that there is no easy ride because of family connections. “We have chosen to work together based on our skills. We have found that in our style of family business, you try to prove yourself by doing a little more and better. We push harder. It is our approach and it works for us.”

The Wood Man Floors

“These floors are locally manufactured in Utah from wood sourced only in the United States.”

–Karen Larson , The Wood Man Floors

Karen Larson and her sons Kyle and Josh make up the crew at The Wood Man Floors. They staff the showroom, run the office and warehouse, and manufacture up to 1,000 square feet of prefinished wood floors each hour. The floors are entirely custom in material, dimensions, color, and finish. These distinctive treatments are perfect for the unique qualities people look for in luxury homes.

The walls of The Wood Man Floor’s Wasatch Front showroom display the possibilities in rows of samples, and Karen, Josh, and Kyle are willing to develop samples of something entirely new that is not in the showroom. Just down the hallway, a glass window looks into the manufacturing area. The well-ordered machines can turn out the flooring as you watch, and the Larsons can complete a fully custom order of prefinished floor within two weeks.

“We couldn’t find the machinery we needed for the manufacturing process, so Josh and I conceived, designed, and built some of our specialized equipment,” Kyle explains.

“These floors are locally manufactured in Utah from wood sourced only in the United States,” Karen notes. “We finish the floors with WOCA oil, a product from Denmark that is completely plant-based and green. It doesn’t generate volatile hydrocarbons and when maintained with WOCA oil products, these floors can last a lifetime.”

This unique business isn’t that old; the three founded it only two years ago. However, Kyle and Josh’s experience working with their mom in a family business dates back to their childhood. “We had a family home business that created wood and metal crafts for the home,” Josh recalls, and Karen adds, “It was quite successful until foreign imports undercut our prices and we couldn’t compete.” The memories Kyle and Josh share are that the home craft business was really fun. “We grew up working with wood products. That’s what we know. We like to work, especially if we can work together.”

Josh and Kyle Larson started in business together installing wood floors in 2006. Karen wasn’t part of this first enterprise; she worked for another wood floor company for 15 years and learned the business. The three Larsons kicked off The Wood Man Floors in September 2015.

“We learned that no one else was manufacturing prefinished floors,” Kyle explains. “Josh and I had been involved enough in installation to recognize how prefinishing the floors enhances the floor’s quality, and it is less burdensome on the homeowner, plus it speeds up the installation during construction. We can also accomplish colors and textures in the plant that you can’t achieve on the jobsite for more variety.” The Larsons are proud that the floors they create are sustainable floors that last a lifetime. Josh explains, “There is never a need to sand these floors down. We brief the homeowners on the WOCA products, and with this care they are lifetime finishes. We create floors that last and remain beautiful.”

To homeowners, designers, contractors, and architects, the biggest difference with prefinished floors is they can check the flooring before it’s shipped to the job site. They can also watch the flooring being made. “The floors are truly hand-finished. We sometimes use a circular band saw for a vintage finish; we use a wire brush to bring out the grain; and we scrape the wood with hand tools,” Kyle describes.

Outside the job, Kyle and Josh can be found recreating together. “We restore cars, go four-wheeling, and build things,” Josh tells. “But, while we are away from the shop, work is always on our minds. It’s our idea time. We talk about work and how we can improve upon what we are doing.”

“while we are away from the shop, work is always on our minds. It’s our idea time. We talk about work and how we can improve upon what we are doing.”

-Josh Larson , The Wood Man Floors

When asked about the worst and best part of a family business, Kyle builds upon the difficulty of getting away that Josh mentions. “Work is always there as a topic. It’s not like a normal business where you get to clock out,” he says. And the best part? “Working with family,” all three agree. Kyle adds, “We love and trust each other. Also, no one says this isn’t my job.”

Kyle calls out another positive benefit of operating a family business, saying, “Clients really like knowing that they are dealing with a family-owned and -operated business and that we love what we do. They see that we really work well together.”

Karen says that family qualities put clients at ease, too. “We are very honest with each other and with our clients. We will tell the truth, even though it might not be what they want to hear. They see that we trust each other to do our part, and they recognize that we will pull together to get the job done. Lastly, and certainly not least, communications are easier, a lot easier, because we are family. Clients can deal with any one of us; there is no preferred point of contact because they know we will share the information with each other and take care of their needs,” she explains.

“No one says this isn’t my job.”

-Kyle Larson , The Wood Man Floors

Karen, Kyle, and Josh Larson are continually thinking about ways to expand their products with new colors and textures and improve and increase production, perhaps by inventing more machinery. Their plan is to not grow too big, but to stay small with personalized custom hand-finished products.

What advice can they offer to other families seeking to go into business? Karen considers this and answers, “We knew what we were getting into and we were prepared. But also, don’t take yourself too seriously. And you have to have trust and communicate without being too emotional.”